5%off Manufacturer Customized IP68 316L Stainless Water Electromagnetic Flowmeter Electromagnetic Flow Meter Price

Package size per unit product 150.00cm * 100.00cm * 120.00cm Gross weight per unit product 100.000kg Manufacturer Custom

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | HKLD |

| Main Application | Water, Wastewater, Diesel Fuel, Fuel Oil, Nature Gas, Corrosive Liquid/Gas |

| Size | DN10-DN800 |

| Sensor | Tube/Flange |

| Application | Industrial Production |

| Type | Vortex Flow Meter |

| Measuring Media | Liquid |

| Measuring Principle | Electrical Principles |

| Measurement Object | Closed Pipeline |

| Certification | CE, RoHS, ISO |

| Meter Accuracy | Piped: 0.5 Class, 1.0 Class |

| Measuring Range Ratio | 150:1 |

| PTFE Lined Pipe | 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150 |

| Rubber Lined Pipe | 40, 50, 65, 80, 100, 125, 150, 200, 300, 350, 400 |

| Transport Package | Wooden Box |

| Specification | make to order |

| Trademark | Vacorda |

| Origin | China |

| HS Code | 90261000 |

| Production Capacity | 100 Piece Per Week |

Packaging & Delivery

Package size per unit product 150.00cm * 100.00cm * 120.00cm Gross weight per unit product 100.000kgProduct Description

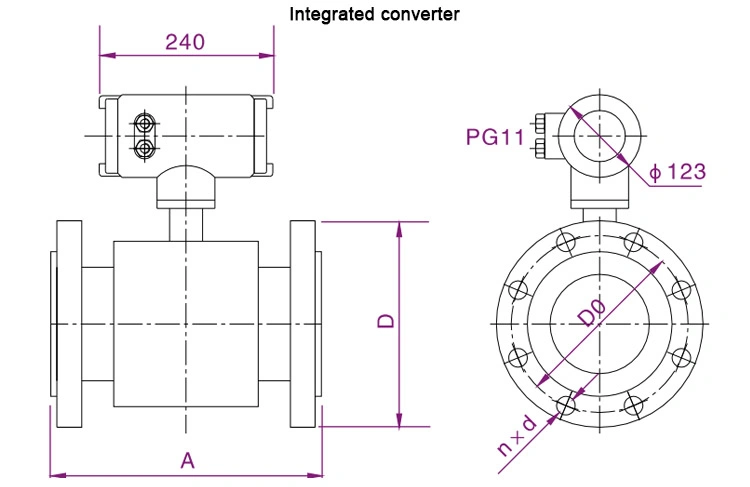

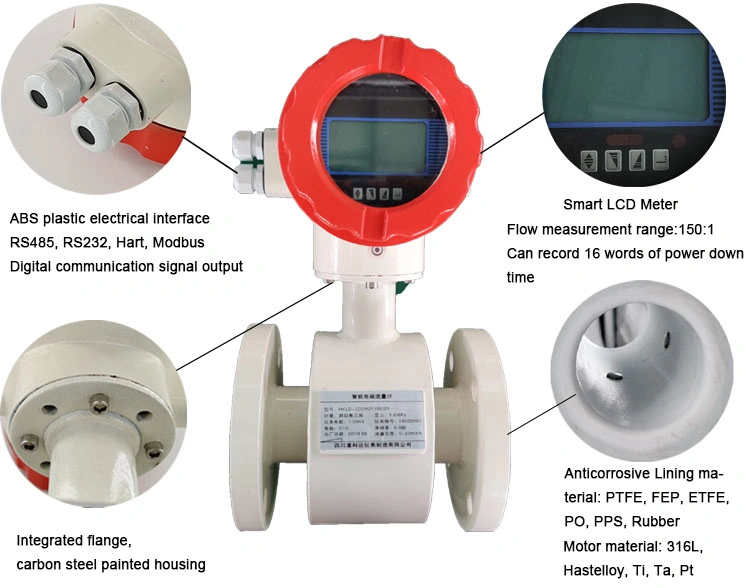

Manufacturer Customized IP68 316L Stainless Water Electromagnetic Flowmeter Electromagnetic Flow Meter Price Production DescriptionElectric medium highly sensitive quality Electromagnetic flow sensor for industry is a fully intelligent electromagnetic flowmeter developed by our company using the most advanced technology at home and abroad. Its electromagnetic converter core adopts high-speed central processing unit. The calculation speed is very fast, the precision is high, and the measurement performance is reliable. The sensor adopts non-uniform magnetic field technology and special magnetic circuit structure, the magnetic field is stable and reliable, and the volume is greatly reduced, the weight is reduced, and the flowmeter is characterized by small flow.Product Features

1. No moving and blocked flow parts in the pipeline, almost no additional pressure loss in the measurement.

2. Measurements results are independent of physical parameters, such as flow distribution, fluid pressure, temperature, density and viscosity.

3. On-site modification of the measuring range available.

4. LCD display, easy to use and simple to operate.

5. Using SMD devices and SMT technology.

6. Using 16-bit embedded processors with fast speed and high accuracy, enhancing the stability of measurement.

7. Anti-interference, reliability, measurement range up to 150:1.

8. Ultra low EMI switch, wide range of power supply voltage.

9. RS485, RS232, Hart and Modbus digital communication signal output.

10. Self-checking function.

Detailed Images

Product Parameters

| PTFE Lined Pipe | 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400,450, 500, 600 |

| Rubber Lined Pipe | 40, 50, 65, 80, 100, 125, 150, 200, 300, 350, 400, 500, 600, 800, 1000, 1200,note: special specifications can be customized |

| Flow Direction | positive and negative, net flows Turndown |

| Measuring Range Ratio | 150:01:00 |

| Accuracy: | piped: 0.5 class, 1.0 class |

| Measured Medium Temperature | Common rubber lining: -20~+60 ° c |

| High temperature rubber lining: -20~+90 ° c | |

| PTFE lining: -30~+100 ° c | |

| High temperature vinyl lining: -30~+180 ° c | |

| Rated Working Pressure | pipeline: DN10~DN65: ≤ 2.5MPa;DN80~DN150: ≤ 1.6MPa; |

| DN200~DN1200: ≤ 1.0MPa | |

| Flow Measuring Range | flow measuring range corresponding to flow rate range is 0.3~15m/s |

| Measured Fluid Conductivity | 5μs/cm (Most with water as the composition of the medium,its conductivity in the range 200~800 Mu s/cm, optional |

| Repetitive Error | +/-0.1% |

Application

Why Choose Us:

1. 23 years of instrumentation equipment production experience2. Product support OEM, ODM, export to more than 100 countries3. The company area 20,000 square meters, and 150+ orders per month4. Provide email, skype, whatsapp provide 24-hour one-on-one technical support service online

Company Information

FAQ

Q: The new magnetic flap liquid level gauge can't show liquid level?

A: 1.check whether there is block in by pass pipe 2.check the the density of medium 3.check whether the float ball is stucked by float ball.

Q: The longest length of magnetic flap liquide level gauge?

A: the length is customized,but in order to be convenient for transport,if the length is over 6m,we recommend

Q: If the float ball is installed at the wrong opposite direction,what's the influence?

A: reading level will be higher than true level,usually higher by length of floatball-70mm

Q: What's installation details of magnetic flap liquid level gauge ?

A: 1.before installation,check specification with label plate. 2.There shouldn't magnetic field within 400m

Q: There is problem in output signal 4--20mA?

A: 1.Check working power supply 2.check wiring 3,check load resistance 4.verify measuring range,zero point

Q: what's specification we need to know before purchasing magnetic flap liquid level gauge?

A: medium density,working temperature,working pressure,material,flange center to center distance,flange standard,whether need 4--20mA output signal;wether need level alarm

Related Products